the control of the alcohol emission

during packaging

The device is equipped with accurate control, during packaging,

of the alcohol emission, in the form of a fine spray,

in the proper amount as required by law

ALC-DISPENSER is an integral part ot any packaging machine. Specially designed for the packaging of bread and pastry products. These delicate products require special wrapping procedures to safeguard them from mould and to offer the consumer an excellent product.

IT RESPECTS THE PRINCIPLES OF ECONOMY AND SAFETY

The use of ALC-Dispenser ensures the effective duration of the product

for the time indicated on the package by the producer

ALC-DISPENSER issues an acoustic alarm and stops the packaging line if there should be any jamming of electromechanical equipment other than the instrument, or if the system should run out of liquid (alcohol) as well as if the operator performs an erroneous action. This will ensure that no product escapes treatment creating problems of mould or other problems at the time of consumption.

Reduces Production Costs

Guarantees teal savings in alcohol consumption. Control of the emission of the exact amount required by law and assurance of precision dispensing keep unaltered the structure, purity and flavour of your products.

Accurate Programming that controls Production

The distribution of alcohol is programmable by the operator. It is easy to use and capable of memorizing the partial amount of liquid dispensed per program and at any time. It will produce a printout relative to the total amount of liquid distributed and the number of dispensing operations performed during each program. 21 programs can be memorized.

Guarantee for your Products

Connected to a centralized or individual distribution unit, it controls dispensing performed at every passage of the product and in the amount proportional to the weight of the product. This prevents any products from being packaged without being treated with alcohol, due to possible negligence of the operator.

Compliance with Safety Regulation

Regarding the workplace and workers assigned to packaging.

Constructed in deflagration-resistant material, it can dispense exact amounts of inflammable and non-inflammable liquids of different viscosities.

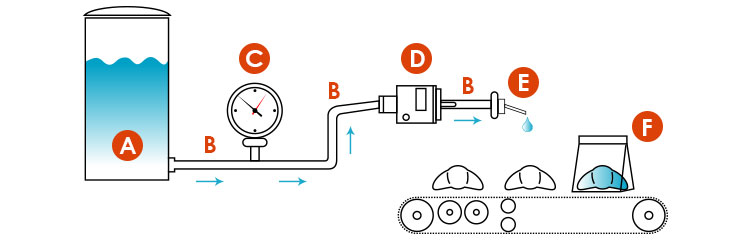

Instructions for Assembly

From alcohol tank (A) pipeline outlet (B) for connection with liquid conveyor reduction unit - pressure gauge (C). The dispenser (D) is provided with an alcohol intake and outlet that are connected to the spray gun (E) positioned over the product to be treated (F). The device is connected: 1) to a 24 V DC power supply - 2) to alarms that stop the packaging machine - 3) to the impulse triggered by passage of the product - 4) to a small solenoid valve mounted on the spray gun (E) to control the opening and closing of the dispensing mechanism.

Alarms And Safety Devices

ALC-DISPENSER is equipped with an excellent alarm system that ensures complete control in case of malfunctions.

- Alarm - dispenser jammed

- Warning no alcohol

- Count of set number of dispensing operations reached

- Dispensing too long! Dispensing time is longer than the package

- No dispensing by packaging machine

| Size (H x L x P): | mm 110x305x280 |

| Weight: | Kg 4 |

| Power supply: | 220 V |

| Maximum power absorbed: | 2A |

| Programming: | Built-in Touch Keyboard |

| Display: | Alphanumeric LCD |

| Construction material: | Flameproof |